All vehicle owners should know this by now: never skip out on your vehicle’s preventive maintenance. One effective way to avoid needing major truck repairs here in Dallas, Texas is to have your truck undergo maintenance as often as necessary to catch areas of potential damage before they can worsen (and end up costing more to repair or replace).

More than just cost-effectiveness, maintenance for trucks is a crucial step towards reducing the number of truck accidents that happen around the United States. That’s why it’s important to have your truck undergo maintenance from a truck repair company in Dallas, Texas that understands the aspects of your semi-truck and ensure the safety of your vehicle.

Here’s what your chosen repair company should be looking at when maintaining your semi-truck.

Our Checklist

Here’s a thorough list of everything that should be looked at:

- Engine oil and filter – depending on your semi model, these may need to be changed.

- Fluid checks – check for fluid leakage and if there’s enough fluid (transmission fluid, coolant, antifreeze, fuel, etc.) in your vehicle.

- Engine and transmission mounts

- Drive shafts or CV joints

- Belts and hoses

- Tune-ups

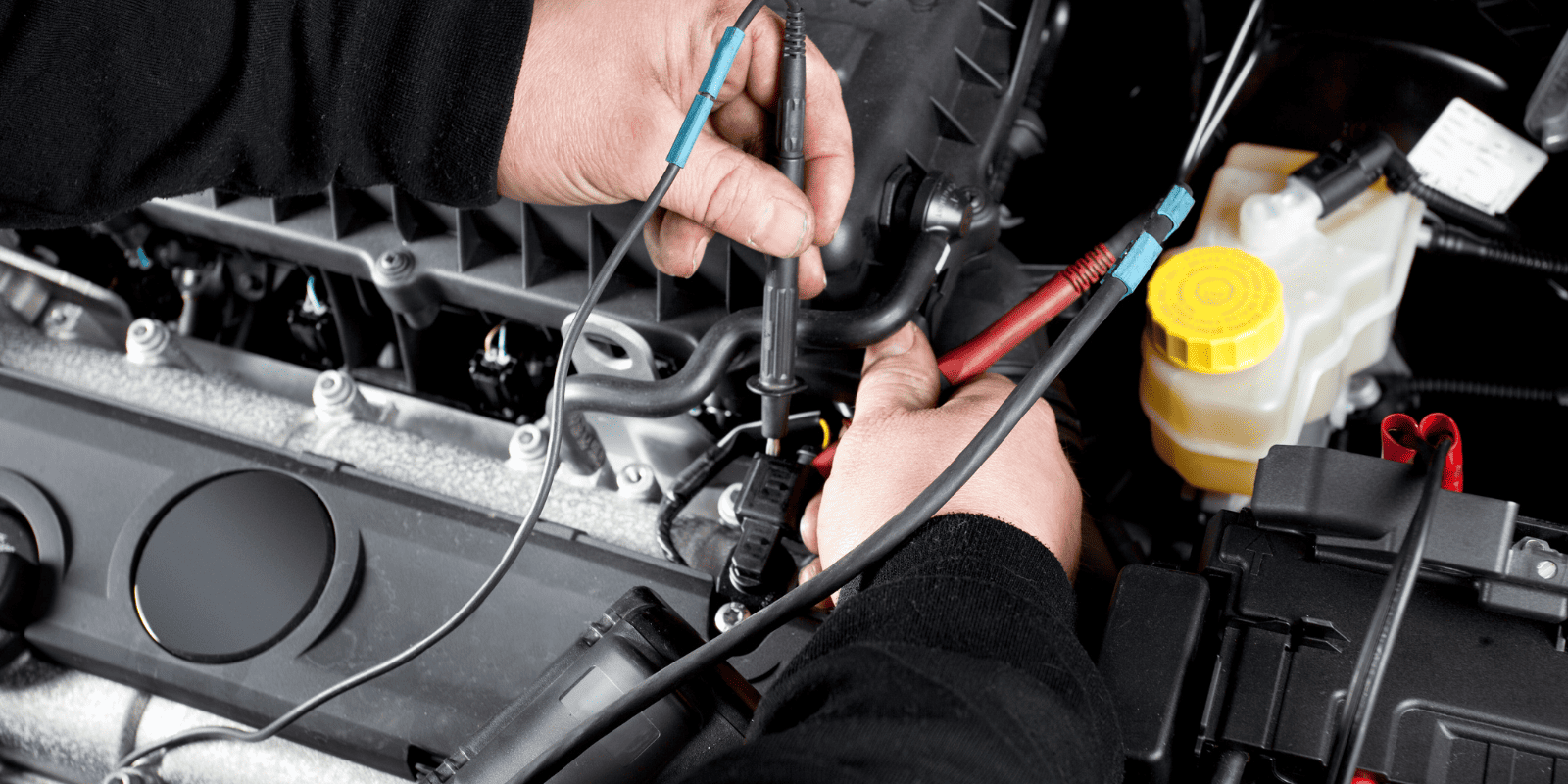

- Electrical components

- Steering, suspension, and braking systems

- Tires, wheels, and rims

- Exhaust

- Undercarriage and frame

- Lights

- Body, glass and mirrors

- Windshields

- Other auxiliary systems

- Mileage

Depending on the model of your semi-truck and other factors to weigh in, your truck repair company may take a look at your mileage. While a scheduled preventive maintenance can reduce the chance of major damage to your vehicle, there’s always a risk of accidents or sudden damage on the road that may warrant an unscheduled trip to the shop.

One example of this is when your schedule indicates not a precise date, but rather to visit a shop once your truck reaches a certain number of miles. Depending on the usage of the truck (light- to heavy-duty semi-trucks), you may need to have it serviced starting at 10,000 miles upwards.

Seasonal Maintenance

During certain seasons, your truck repair shop may perform additional maintenance steps to mitigate the increased risk of accidents or damage during that time. For instance, truck driving during the cold winter months may need you to replace your tires that are less likely to skid in icy road conditions, while hotter summer months may mean your air conditioning unit may need to work harder than it normally does.

Here are a few additional things your repair company will check during seasonal maintenance during the summer:

- Coolant – Coolants should be drained and flushed at least once a year to make sure that clean coolant remains in your system.

- Radiator – Inspecting the radiator for corrosion and damage. The radiator cap is replaced whenever the coolant is drained.

- Air conditioning system – Cleaned when necessary to ensure its performing its best, especially during the hotter periods of the year. Damaged cooling coils and debris buildup may cause your system to work harder than it really needs to. In the winter, the heater is tested to ensure it functions properly.

- Water pump – Examined for leaks and performance to ensure your engine operates at the optimal temperatures (especially during the hotter seasons).

On the other hand, winters can also have a negative effect on your truck especially when you are driving through extremely cold weather, snow, ice, and other debris brought about by the season. Additional maintenance can include: - Engine heaters – Depending on whether your semi’s model is using a block heater or oil-pan heater.

- Diesel engines – Some types of diesels cannot withstand extremely cold temperatures. You may need to replace your fuel to ensure performance while driving in areas where the temperature can drop below 10 degrees Fahrenheit.

- Windshield and windshield wipers – During the winter, windshields are more likely to break due to the stress caused by the temperature. Chips and pitting on the glass can make it vulnerable to cracking. Damaged windshield wipers can increase this risk and will need to be replaced.

As the saying goes, prevention is better than the cure – especially when it comes to investments like semi trucks. A good maintenance program is both proactive and reactive, so it’s important to choose your truck repair company in Dallas, Texas carefully.

WTX Truck Repair, LLC gets you and your truck back on the road in no time without sacrificing the safety and quality of the truck you’re driving. Our skilled mechanics have years on their belt lifting semi-trucks to their best possible state and achieving top customer satisfaction.

Get in touch with WTX Truck Repair, LLC today.